As the information, we gain from new technology and processes become readily available this keeps the flow through innovation and R&D moving forward. What we learn during R&D aids change and progression.

But…. We are still bound by these traditional ways of designing right? Very much stumbling across problems as new undiscovered advancements arise or being presented by new challenges which appear because of changing environments.

So, we change our design to suit a new physical material because of the environment it will be driven in, for example, a change in temperature means a change of most materials and new testing and validation.

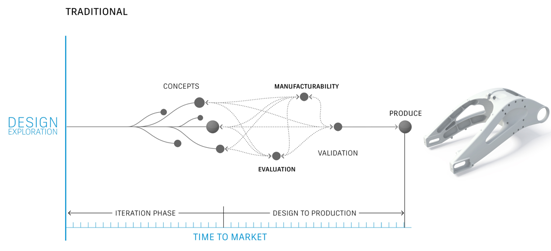

These design iterations take time, our most underutilized tool. As humans we have a brain capacity, right? When normal life tasks and our schedules interrupt our need to think, we are bound by our brain capacity and the ability to focus. So, in fact, we are limited by our ability to fully embrace the traditional design process. This is where traditionally we use design reviews, we get together, introducing more brain power with different skill sets to expand our concepts of choice.

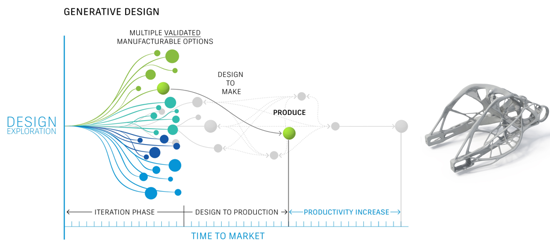

What if there was another way, what if a designer could gather all the information for concepts upfront in a different way. Interacting with the design process around constraints based on the environment your design will live in, what materials it could be made of and how it will be manufactured, building a set of specific criteria.

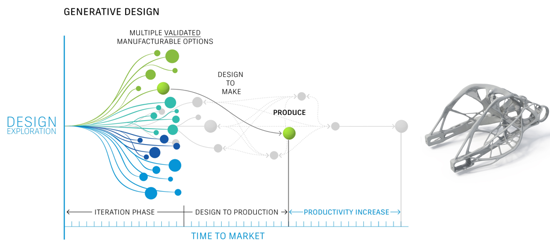

Then take this information gathered, and Artificial Intelligence (AI) will create a mass of possible iterations of your design, how would you feel about that? Let’s be honest here, do you feel it would diminish your creative knowledge? Would you feel a little robbed of your talent as a designer? Well, I felt this way and I am sympathetic to these feelings, but think about this if you use the traditional approach then you will come up with say a strong 3 concepts/results! You will take these 3 concepts/results and eliminate 2 to get to 1, but the process is not over here, you still must make sure your design can be made. Thus, moving to the next stage of your design, as a designer you must now involve engineering and manufacturing if they haven’t been involved to this stage.

This would very much still be the same if you use AI to help, in fact, you’re just using the computing power to churn out possible designs, but your human feelings and interactions are what make you different and therefore you will always be the driving force behind the gut feelings you have in design, with the years of experience you have gained using the traditional design process. Using AI just means you have more time to play after your software has churned out of the possible design concepts.

Using AI will give you the main boost you need to front-load the design process, creating 100s of possible designs, which can consider weight, cost and the manufacturing process.

Now you have an idea of what the process can look like, what applications are currently available and provide AI in an environment that you as a designer are already familiar with. I have personally been working with Autodesk Fusion 360 for several years now, not only for CAD or CAM but now with a focus on Generative Design.

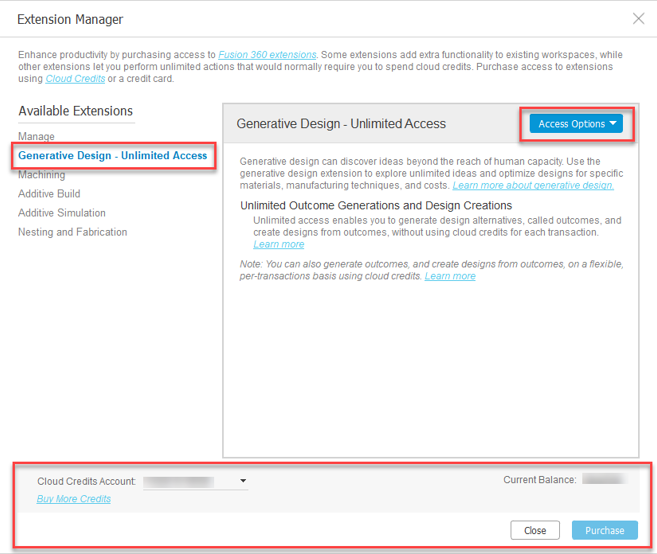

Autodesk Generative Design has been part of the Fusion 360 application since 2018. Since then, users have experienced this workspace with several different pricing models. The reason for this is because the functionality in this environment has continued to advance over the years. With a focus on the computing power in the cloud.

At its core, generative design is an exploration environment allowing designers or engineers to input crucial criteria into a simplified and advanced interface that does all the leg work. Parameters, like performance and spatial requirements, materials, manufacturing methods and cost constraints are all taken into consideration. The software then explores all the possible permutations for a solution and displays your results in a filtered area for investigation.

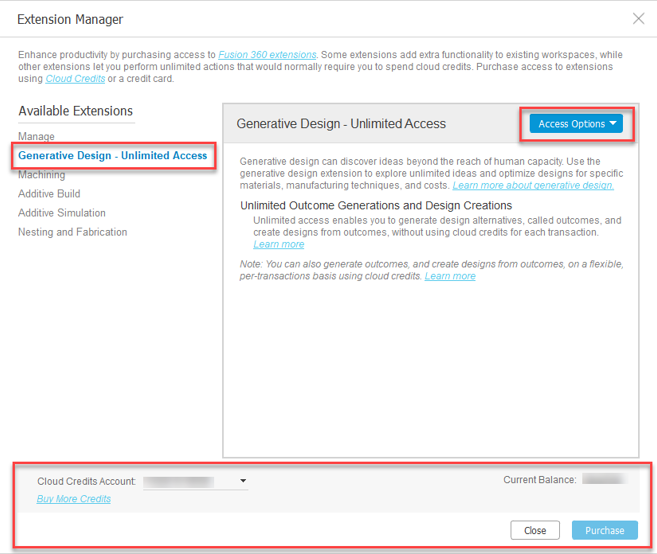

How to purchase and utilize Generative Design?

Currently, as I write this Autodesk’s Generative Design extension is £234 a month or £1848 a year. A month or yearly subscription to the generative design extension will mean unlimited access including unlimited generation of outcomes. This can be purchased via Symetri or through the Fusion 360 application

The charge for generating an outcome from generative design is 33 cloud credits. Cloud credits can also be bought in batches allowing flexibility when using any of the cloud solving features of Fusion 360.

Autodesk tends to discount these prices at various times in the year, keep an eye out for these discounts or try a 7-day free trial to see what types of results you can achieve.

I understand that generative design will not be suitable for all design applications, but if you currently have a problem you think is well suited to generative design, whatever that may be why not give it a go?

If you have a current/future project you feel this would be suited to, then contact us, at Symetri, we can walk through the journey with you, help you determine what generative design can bring to the internal design team. Lean on us and we can drive the process with you, challenging each other to achieve your desired outcome. Along with Autodesk, we can advise on the use of generative design as well as all working areas of Fusion 360 and the Autodesk advanced manufacturing solutions.

Symetri provides free 30 min consultations, so feel free to get in touch and we can start this journey together.