This blog will explain what Fusion 360 is and introduce the Design Workspace, Generative Design Workspace, Rendering Workspace and Animation Workspace.

So, what is Fusion 360?

Fusion 360 is the first collaborative, cloud-enabled CAD, CAM, CAE, and 3D PCB design platform that allows designers and engineers across the industry to connect, collaborate and ultimately bring products to market faster than ever before.

How can Fusion 360 connect users?

Design in the manufacturing industry can mean many things.

Are you a product designer? Do you primarily use Solid Model design? Do you require surface modelling techniques? Do you require FEA simulation to prove aspects of the design? How are your models used downstream? For example, do you require electrical components design to help finalise the size requirements of your product? How will the product be manufactured? Are you using CNC machining techniques to produce a working product? Do you require specialist work holding to allow the machining of the product? Can you require a rapid prototype of the product to help with ergonomics or provide a customer with a sample of what the product will look and feel like?

The above aspects of a design process can be challenging to pull together when working across different departments, design platforms and user skill sets. With Fusion 360, all these aspects of the product design and manufacturing workflows are merged, allowing users to access key design information required in their specialist areas whilst having the capability of capturing all design and manufacturing related information on one easy to navigate platform.

Fusion 360 also brings different hardware users together as the platform is supported on Windows and Apple Mac solutions.

How does the platform help users realise their design and manufacturing capabilities and bring products to market faster?

A product designer uses Fusion 360's in-depth design tools to develop the concept(s). A design engineer then takes the idea and starts to plan how the image can be brought to manufacture. This could include material selections, size requirements, surface finishes and tolerances, paint specifications etc., generating BoMs to be included with in-depth technical drawings alongside documentation such as FEA analysis and reports. The Electrical engineer starts to generate the required PCB designs to ensure the components fit into the design concept and advise where changes may be necessary.

Each department has access to the same model information and can collaborate using the Fusion 360 Team, where mark-ups and comments can be stored. Reports generated highlighting each stage of the design process. The manufacturing departments can also start to take the models and produce toolpaths strategies required to machine any Jigs, Fixtures, and Soft Jaw work holding devices and plan any other machining requirements to ensure the product can be manufactured efficiently and in the safest possible way.

With all this information being generated, a realistic rendering of the design concept can be used to help generate pre-sales visualisation of the product or potential marketing material to showcase the finalised design and build awareness of the new product being brought to market.

With Fusion 360, all the above departments use the same model information, allowing each department to contribute to the design and successfully capture required specialist knowledge by actively collaborating to ensure all project information required to design and manufacture the new product efficiently is available. Any changes needed throughout the process are noticed and tracked throughout departments instantly. This enables each department to work on the specialist subject early in the design stage.

Let’s take a look at some of the Fusion 360 Workspaces and User Interfaces:

The Design Workspace:

This workspace offers Product Designers and Design Engineers comprehensive tools with both top-down and bottom-up modelling techniques where Solid Modelling, Surface Modelling, Mesh preparation and modification, and Sheet Metal and Plastic Part design tools are readily available.

Users can also take advantage of the automated modelling features where designs can have specific design constraints attached. Fusion AI will then produce multiple iterations of the design based on the constraints giving the designers multiple outputs of the same design, helping reduce the over-engineering of components, - whilst potentially reducing waste created in the manufacturing process.

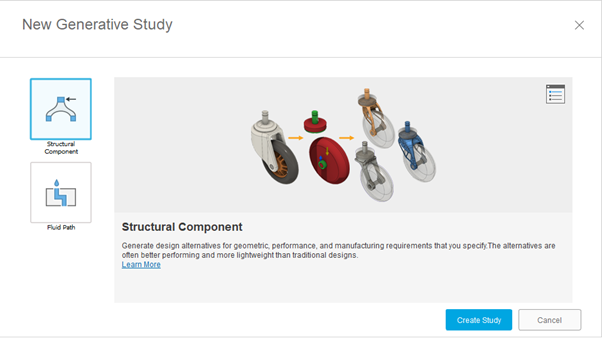

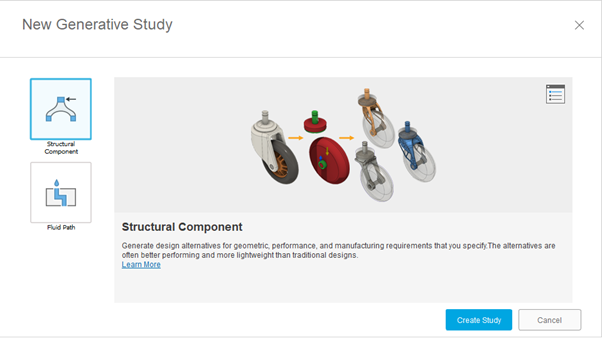

The Generative Design Workspace

Design Engineers can also take advantage of the Generative Workspace, which uses similar AI technology as mentioned previously with Automated Modelling techniques but takes the possibilities to the next level.

Generative Studies define a set of data that describes a specific design-related problem. Design objectives such as functional, manufacturing, and mechanical requirements alongside material types and any performance related criteria can be captured in the study setup, which will generate a set of designs that meet the pre-set requirements once performed.

Multiple studies can be created and cloned, and the data ultimately captured throughout the design process giving further design flexibility with numerous product outcome possibilities. Why would you not want to explore this feature?

The Render Workspace:

The Render Workspace offers users high-quality realistic rendering features allowing designs to be visualised as a finished product. Over time many companies I have worked with have yet to realise precisely how much their historical designs are worth, especially when they can be showcased for marketing purposes, pre-sales, sales activities, high-quality technical documentation, website articles and offerings.

Fusion 360’s Render Workspace allows users to apply materials and appearance options to a given design quickly and apply and manipulate scene settings. You can add decals that blend perfectly with the model geometry and materials/appearance selections, and the ability to adjust texture map controls amplifies the visualisation outcome.

Fusion 360 has canvas and full cloud-render capabilities allowing clear and comprehensive realistic visualisation of the product being designed.

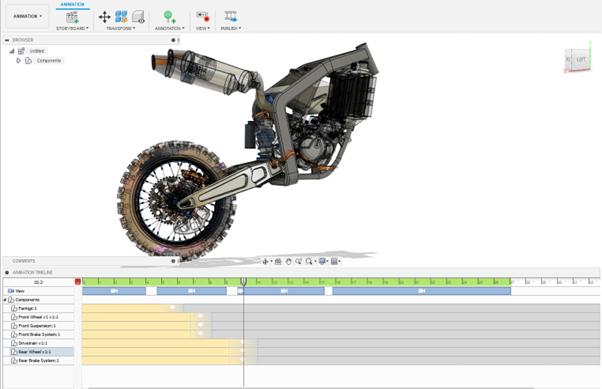

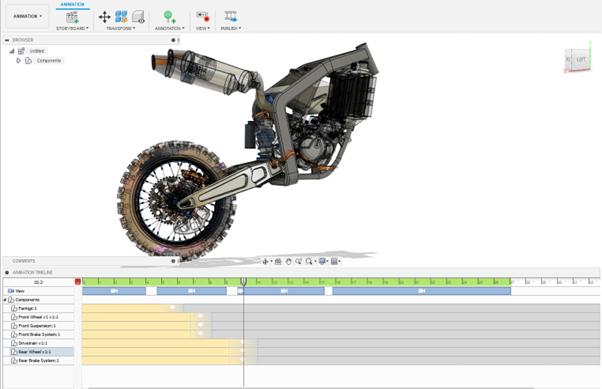

The Animation Workspace:

Fusion 360's Animation Workspace allows users to generate animations of their design and output to an AVI file format. The animations could include general product showcasing, explosion or reverse explosions of their products and can be used for marketing, presentation requirements or even training materials.

My experience of using animations in an industrial training setting allows users to understand a given workflow quickly. For example, when changing components on a machine, an animation accompanied by technical documentation in the form of an electronic user manual where the reader can learn about a process but then quickly visualise how something is done. This increases workflow efficiency and delivers a better safety perception of complex tasks requiring a specific step by step requirement.

The Fusion 360 Animation Environment looks and feels like the Autodesk Inventor Presentation Environment and is very easy to use, where manual and automated techniques for positioning components can be placed on an easy to navigate the timeline.

Why would you not want to use these features and unlock the untapped potential of your CAD data?

In my next blog, I will detail the workspaces available in Fusion 360, Simulation, Manufacture, Drawing and Electrical.

For more information about Fusion 360, please visit our Website. Symetri also offers a wide range of training courses, from Essentials Training to Advanced Multi-Axis Machining training. These training courses are designed to get you up and running with the technology as quickly as possible. Take a look at our Fusion 360 Training courses.