Consider a closed-loop system made up of a boiler, a pump, and several radiators. Revit will see this as two separate systems that would require a flow rate to be added to both the flow and return side of each radiator. As such we have two separate systems, and two sets of Mechanical Flow information where in reality this is a single flow and return system.

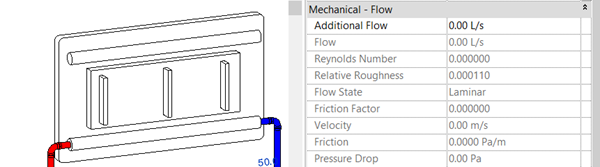

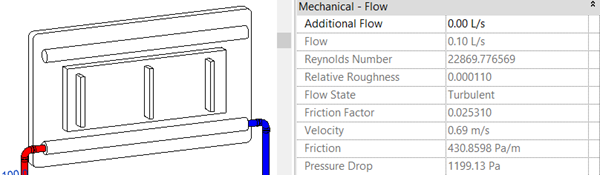

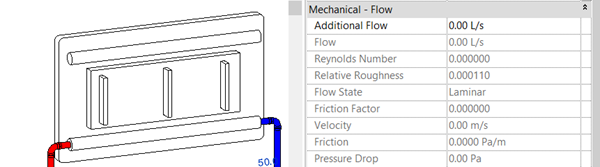

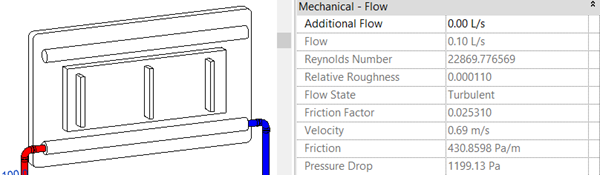

The problem we have with this arrangement is that if the flow rates were to be removed or altered on either the flow side or the return side of one or more of the radiators, there would be either no data or inconsistent data when interrogating the system pipework. In the first image below the flow rate has been removed from the return side of all radiators resulting in no values for that half of the system, but if we look at the flow side in the second image there is Mechanical Flow data.

Closed Loop Systems

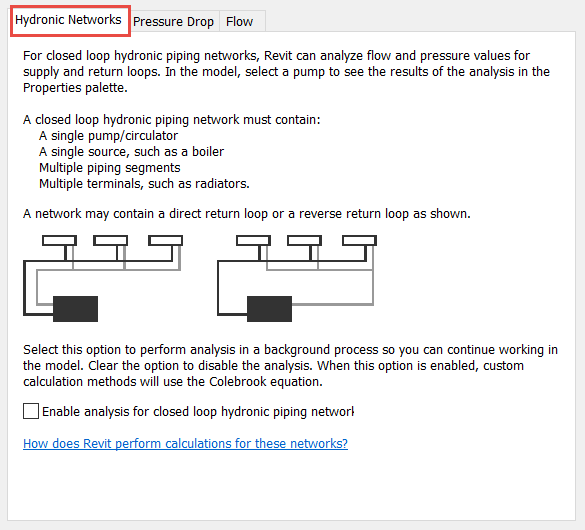

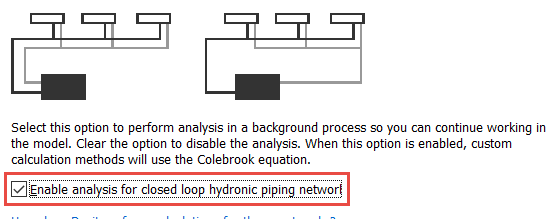

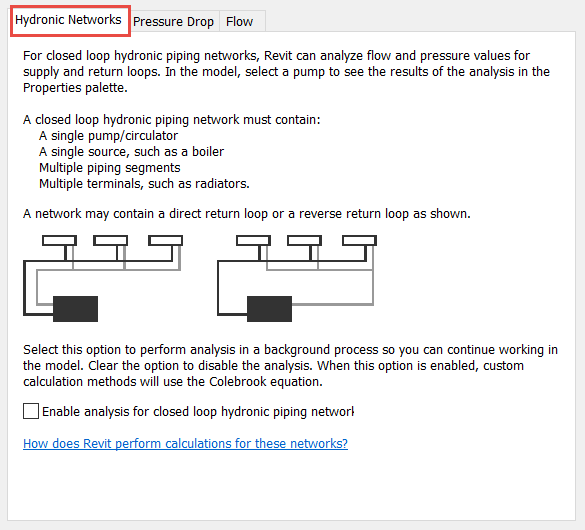

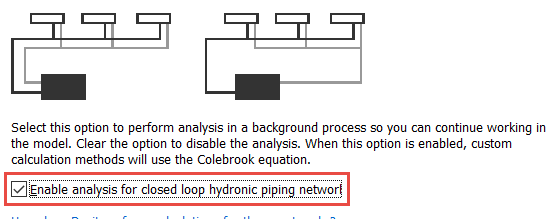

The issue of treating this arrangement as a single flow and return systems in Revit MEP can be addressed using the Hydronics Networks feature, which was introduced in the 2018 release of Revit MEP. Below we see the option in Mechanical Settings to utilize the feature.

There are just two simple steps you need to take:

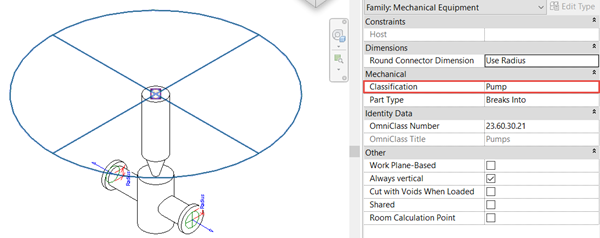

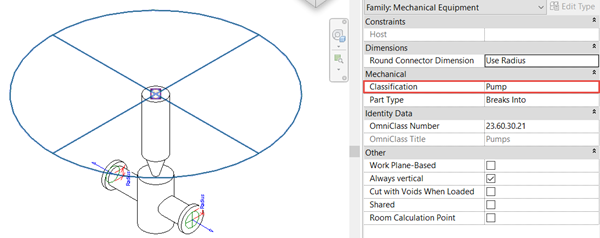

1. Set the system’s pump Classification to Pump in the family editor and load it back into your project.

2. From Mechanical Settings enable the option shown below.

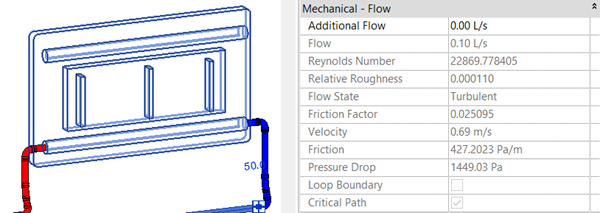

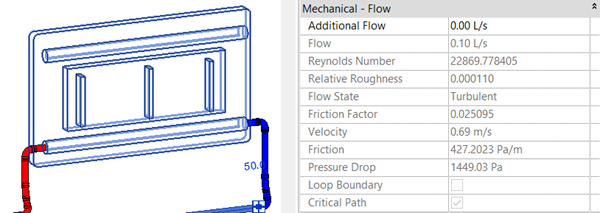

What does our flow and return system look like now?

If we interrogate the same section of pipe as before we see that even though there is no flow rate value added to the return side of the radiator there is Mechanical Flow data in the properties.

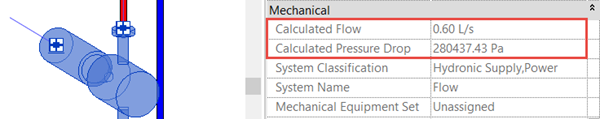

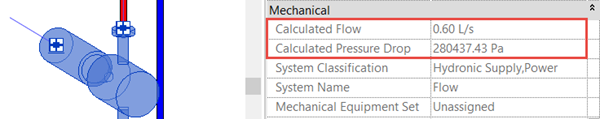

If we look at the pump properties, we will see additional values for Calculated Flow and Calculated Pressure Drop for the complete flow and return system. Properties that were previously unavailable, without creating a pipe pressure loss report and adding the values together.

Using this feature allows you to interrogate values in your flow and return system without the need for creating reports and adding values together repeatedly. It also means that you will not have to apply separate values to both the flow and return sides of your radiators (or whatever is in your closed-loop system).

If you are interested in learning how to use Revit or Revit MEP more effectively, then view our website for a list of available Revit training courses here. Alternatively, contact us directly and we would be happy to discuss your specific needs with a tailored Revit training course.